TEST & TAGGING

AUTOCAD ELECTRICAL DRAFTING AND DESIGN

Test and Tag is a process of carefully visually inspecting each appliance for damage to flex, connections, guards, covers and plug by a competent technician. Once the technician is assured the item is safe to electrically inspect, the items insulation, earthing and polarity may be tested to ensure it is electrically safe.

Test and Tag is a method of ensuring compliance with Australian WHS and Electrical Safety regulations and workplace safety.

Portable appliances such as power tools and kettles are items that are most frequently handled by workers are also the most open to abuse and hostile environmental conditions – which can cause them to become electrically unsafe. Under most state and territory regulations, these appliances in hostile operating environments must be tested and tagged on a regular basis to ensure their safe operation.

In order to comply with WHS legislation and satisfy your duty of care, all workplaces Australia-wide must be able to demonstrate safe systems of work; as such detailed records of the test are kept by the technician.

Our qualified trades can Test Tag and repair all your appliances ensuring compliance is met for your site! A full follow up report will be completed and any unsafe defects rectified.

All our testing equipment is NATA Calibrated and Inspected.

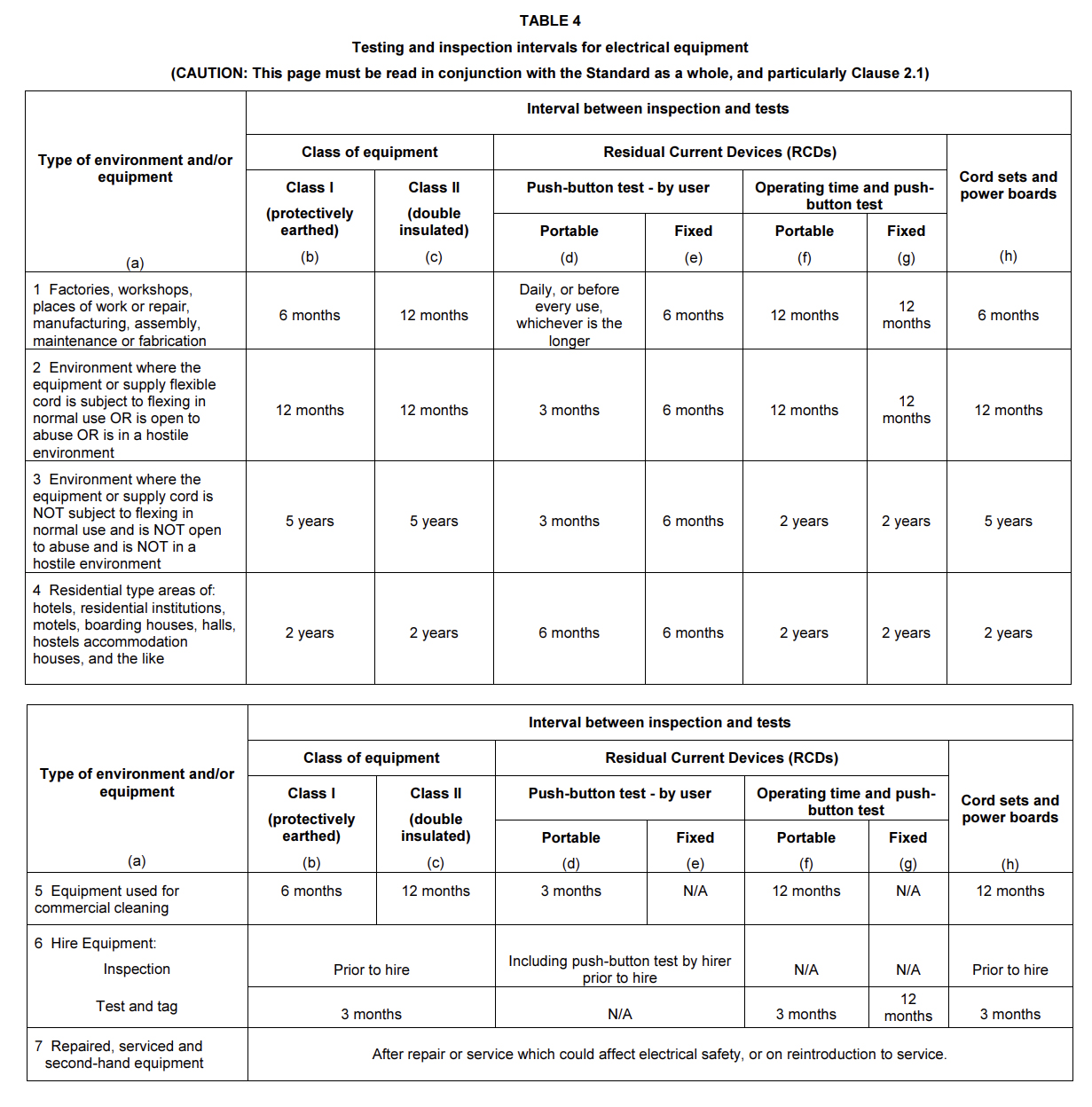

AS 3760 Standard – Testing Intervals